Piping Stress Analysis and Piping Engineering Services

Download an Information Package

Piping Stress Analysis

Piping Stress Analysis is our specialty. Our primary focus is to provide expert piping engineering services. Combined with specialized training and depth of experience, we utilize industry leading tools, technologies, and methodologies to provide practical solutions.

Static Analysis

Dynamic Analysis

Transient analysis deals with transient fluid properties, such as pressure pulsation, mechanical vibration, valve closure, pump start/stop, relief events, slugging, and water hammer.

These factors can be present in normal pipelines and facility piping.

Reciprocating Compressor piping may resonate with mechanical vibration or pressure pulsation.

Slugging in Pipelines occurs in multiphase systems. The slug causes significant forces at changes in direction and can result in piping failures or damage to adjacent equipment and piping.

Mechanical Vibration Measurement and Analysis analyzes transient response of a system to excitation forces. This can be a simple natural frequency comparison with excitation frequencies, a force spectrum analysis, or a time history analysis. Sometimes the nature of the vibration being experienced, vibration measurements are required to determine the cause. Measurements can also be used to confirm design corrections are effective. We are experienced with flow induced vibration problems, as well as pulsation or acoustic vibration situations.

Water Hammer Analysis addresses events which can cause pressure surges resulting in equipment failures in pumps, turbines, and valves. Diagnosing and removing potential causes of water hammer events minimizes failure risk. Water hammer can be caused by sudden valve closure or pump trip, start-up/shut-down of facilities and equipment. These events can cause unexpected and uneven fluid forces; equipment and systems must be designed with this in anticipation to prevent failure.

Equipment Piping Design

Piping connects various pieces of equipment together to form a process system. Each piece of equipment has limits to how much load it can resist from piping. Pi Engineering ensures all designs adhere to prescribed standards, codes, and preferences for difference pieces of equipment.

Equipment types may include, for example: air coolers, compressors, expanders, pumps, pressure vessels, tanks, heat exchangers, steam generators, and turbines.

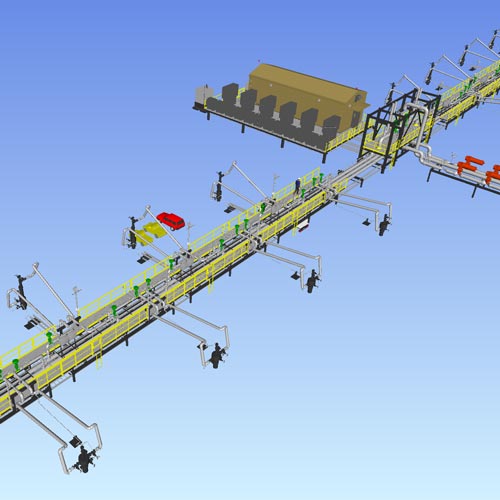

Plant & Facility Piping

Pi Engineering has experience with all aspects of plant and facility piping, and specializes in the following facility types:

- Steam Assisted Gravity Drainage (SAGD)

- Cyclic Steam Stimluation (CSS) aka 'Huff and Puff'

- Heavy Oil

- Petrochemical

- Solar Thermal

- Gas Plants

- Oil Batteries

- Pipelines

- Refineries

Piping Engineering

Deciding on various piping engineering specifications, standards, and selections requires specialized expertise and knowledge. Pi Engineering offers specific consultations in:

- Material Selection & Specification

- Support Standard Development

- Valve Specification & Selection

- Spring Support Selection

- Line Lists, Line Designation Tables (LDT)

- ABSA/BCSA Piping Design Registration

Download an Information Package

Grey Owl Engineering

Capital Engineering

Pembina

Capital Engineering

Work With Us

Contact Us to Inquire About a Project.