Field Services

Download an Information Package

Strain Gauging

Pi Engineering has successfully deployed strain gauges in many environments ranging from remote pipeline installations to the inside of the firebox of a boiler. Strain gauges measure strain, or the “stretch” in a material. This is useful to validate analytical models to ensure that the measured strain and stress matches what the computer simulations predict.

Strain gauging can be used to measure static and dynamic strain. The strain can be converted into other useful quantities such as stress and loads.

In many cases strain gauging existing equipment or piping is cheaper than performing a full computer analytical model with the added benefit of being empirically validated. The strain gauges can measure absolute strain, making them an extremely valuable source of information for what is happening in the real world.

Contact us today to see if strain gauging can help you diagnose and solve your piping and equipment issues.

High Sampling Rate and Resolution Pressure Recording/Pulsation Measurement

Pi Engineering is capable of taking measurements at extremely fast intervals across hundreds of channels. This can be used for a wide variety of applications such as pulsation or transient measurements.

Many types of pumps and compressors create pressure pulses that can be catastrophic if they become too large. Pressure pulsation is a rapid pulse or pressure that can be hard to measure with conventional equipment. Pi Engineering’s purpose-built data acquisition systems have the resolution and sampling rates needed to measure pressure pulsation across a wide variety of equipment.

Once the pressure pulsation values are known a detailed analysis can be performed to ensure equipment and piping is operating safely.

The same equipment can also be used to measure discrete pressure events such as pump trips, valve openings, flow transients, etc.

Contact us today with your pulsation questions.

Vibration Measurement and Dynamic Analysis

All rotating and reciprocating equipment vibrates. A small level of vibration is acceptable. When the vibration becomes too large, issues such as fatigue, failures and cracks, premature wear on internals, noise, excessive movement, containment loss, and less efficient operation can emerge.

Vibration has many sources such as:

- Mechanically induced vibration from equipment or outside sources

- Flow induced vibration

- Acoustic vibration

- Resonance

Pi Engineering can assist you in the measurement, analysis, and the engineering remedy (if required) to all your vibration issues. One of the largest issues with performing a vibration analysis is quantifying the vibration. This is where recording the vibration at site provides an invaluable resource for an accurate analysis.

Long Term Data Acquisition

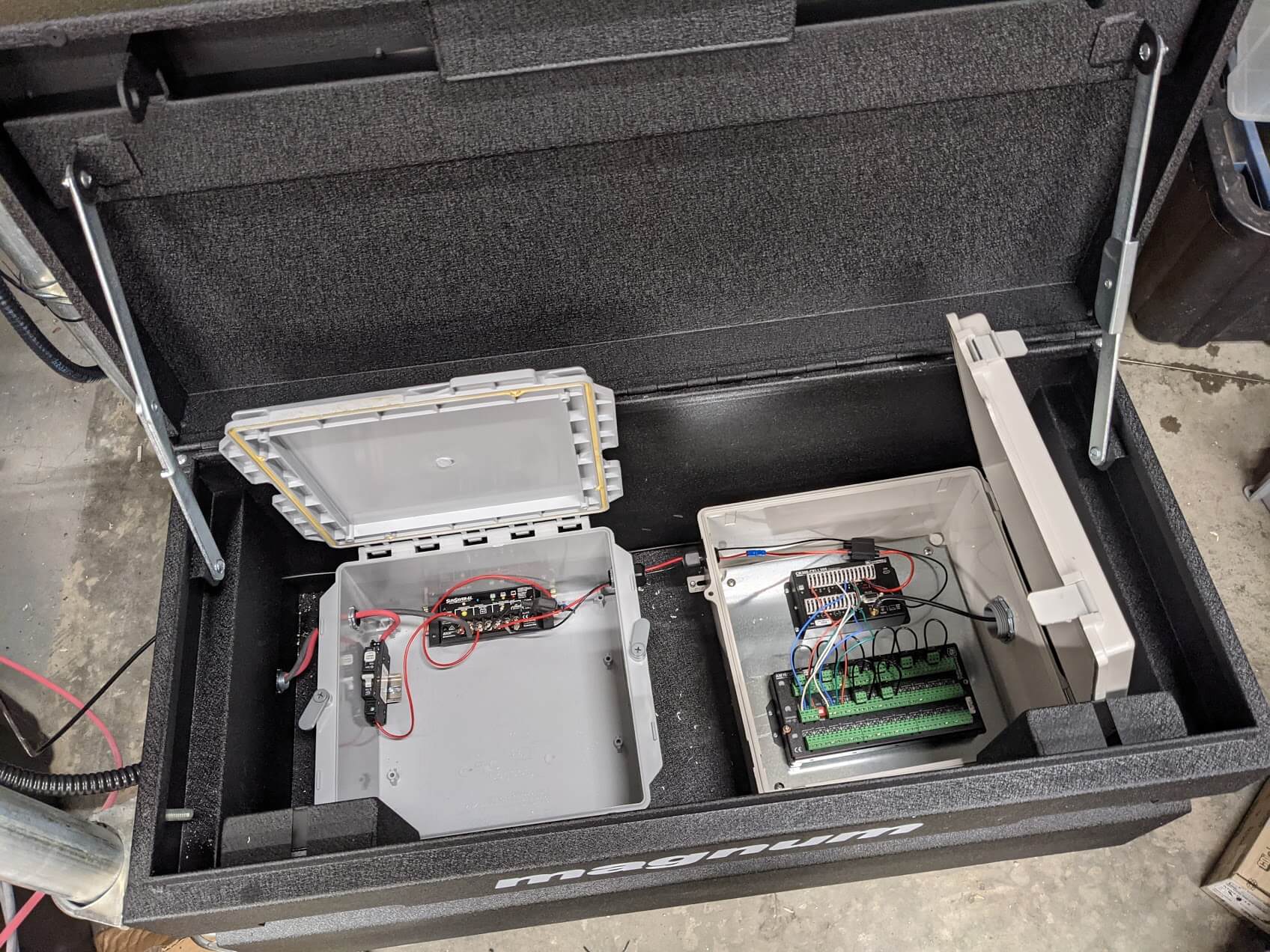

Many events that happen are unpredictable. In these circumstances, long term data recording provides the best solution for capturing the event that needs to be measured.

Pi Engineering’s hardware has been temporarily deployed for months at a time to capture discrete events in complex systems where the root cause of the issues was unknown and unpredictable. By comparing the long-term data recording with the site measured SCADA data we were able to help the client identify both the magnitude of events, the effect it had on their system, and correlate it to the operation of the facility to determine the cause of the event.

Remote Data Acquisition

Critical assets are not just located in manned facilities. Some require significant efforts to observe and would be extremely costly to repair due to their remoteness. Pi Engineering has installed remote data acquisition units on remote pipelines to accurately monitor the strain in the line.

The strain in a pipeline can be used to determine how heavily loaded the pipeline is. The pipeline’s “health” can be determined by comparing the strain to pre-calculated values.

This can be used in a wide variety of circumstances such as in unstable geotechnical environments like slide prone slopes, muskeg, or low-quality soils to ensure the pipeline is operating safely. Remote data acquisition can also be used to monitor your other remote assets.

Pi Engineering can assist you by providing equipment and instrumentation services for temporary installations or assist in designing and supplying systems for your permanent monitoring needs.

Critical Asset Load/Stress Verification

Critical assets, such as large compressors, pumps, or turbines, often have low allowable nozzle loads to operate properly. Overloaded nozzle loads can have many negative consequences. Premature equipment wear, vibration, fatigue cracking, and containment loss are all possible consequences of overloaded nozzles.

Instrumenting the nozzles of critical equipment can be done to monitor the nozzle loads through bolt up into operation to ensure the equipment is not overloaded and operating within its specifications.

There are many loads that cannot be accurately predicted through conventional computer modelling. Loads from misalignment, bolt up, and equipment movement can be difficult to quantify and predict. Instrumenting the equipment nozzles provides empirical measurements that verifies that actual loads on the nozzles from all sources.

Field Engineering Construction Support

Complex piping arrangements can use all kinds of engineering controls to ensure safe operation: spring supports, expansion joints, anchors, and guides. The path of construction can be just as important as the final arrangement in complex piping systems. Pi Engineering can provide field engineering construction support to help ensure things progress as intended to maximize construction success.

Download an Information Package

Grey Owl Engineering

Capital Engineering

Pembina

Capital Engineering

Work With Us

Contact Us to Inquire About a Project.