Finite Element Analysis, or FEA, allows engineers to model and analyze complex systems that would be impossible or impractical to solve by hand calculations alone. With FEA, engineers can break down a complex system or structure into smaller, simpler parts or elements, and then use numerical methods to solve for the behavior of each element. These element solutions are then combined to give an overall solution for the entire system.

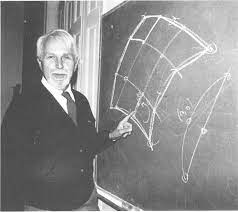

While the origins of FEA can be traced back to the work of engineers and mathematicians in the 1940s and 1950s, the modern development and widespread use began in the 1960s with the work of Ray Clough, Richard Courant, and Olgierd Zienkiewicz. Zienkiewicz is often credited as the father of modern FEA for his pioneering work in developing numerical methods and algorithms for solving complex engineering problems using the finite element method. Zienkiewicz developed new numerical methods for solving complex engineering problems using the finite element method (FEM). He developed a number of innovative algorithms and computational techniques that made FEA practical and efficient for solving large-scale problems. Zienkiewicz also introduced adaptive meshing, which allowed for more accurate solutions with fewer computational resources.

FEA can be used to analyze a wide range of physical phenomena, including stress, heat transfer, fluid flow, and electromagnetic fields. It has revolutionized the design process by allowing engineers to optimize and refine their designs before building prototypes or manufacturing parts, saving time and money. At Pi Engineering, FEA is used to analyze pipe supports, heat transfer, vessel nozzles, pressure vessel design, vessel supports, lifting lugs, and piping components such as tees and bends. For a comprehensive description of how FEA can help in piping, see our FEA services page.