We get it. Sometimes your shiny new pressure-containing equipment doesn’t stay shiny or new for any number of reasons; it may be in service in a corrosive environment, developed a crack, has been put into a new service due to a change in operating process, or just plain suffered a “Bubba stain.” For whatever reason, your pressure containing equipment no longer meets the construction tolerances or requirements of the original code of construction.

While replace-in-kind is often an option, this is sometimes not the preferred option due to down-time, procurement related challenges, or simple economics. This is where fitness-for-service, or FFS, comes into play. Fitness-for-service, as codified in API 579-1/ASME FFS-1, is a collection of technically sound and recognized methodologies that allows one to rationally assess the current condition of a piece of pressure containing equipment to operate under a set of one or more design conditions. The conclusion from a FFS assessment is generally one of: 1) the equipment is fit to operate in its current state, 2) the equipment should be re-rated for less severe service, or 3) the equipment is not fit-for-service and should be repaired or replaced, with other variations appearing occasionally in practice.

While API 579-1/ASME FFS-1 is particularly tailored for use with the following codes and standards:

- ASME B&PV Code, Section VIII, Division 1

- ASME B&PV Code, Section VIII, Division 2

- ASME B&PV Code, Section I

- ASME B31.1 Piping Code

- ASME B31.3 Piping Code

- ASME B31.4 Piping Code

- ASME B31.8 Piping Code

- ASME B31.12 Piping Code

- API Standard 650

- API Standard 620

- API Standard 530

The methodologies of API 579-1/ASME FFS-1 “may also be applied to pressure containing equipment constructed to other recognized codes and standards, including international and internal corporate standards.”

API 579-1/ASME FFS-1 explicitly provides procedures to carry out the following assessments:

- Assessment of Existing Equipment for Brittle Fracture (Part 3)

- Assessment of General Metal Loss (Part 4)

- Assessment of Local Metal Loss (Part 5)

- Assessment of Pitting Corrosion (Part 6)

- Assessment of Hydrogen Blisters and Hydrogen Damage Associated with HIC And SOHIC (Part 7)

- Assessment of Weld Misalignment and Shell Distortions (Part 8)

- Assessment of Crack-Like Flaws (Part 9)

- Assessment of Components Operating in the Creep Range (Part 10)

- Assessment of Fire Damage (Part 11)

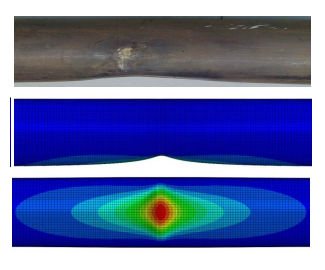

- Assessment of Dents, Gouges, And Dent-Gouge Combinations (Part 12)

- Assessment of Laminations (Part 13)

- Assessment of Fatigue Damage (Part 14)

For each assessment type, API 579-1/ASME FFS-1 generally offers three levels of assessments, Levels 1, 2, and 3, with data and experience requirements progressively increasing with each increase in level. The benefits of each increasing analysis level are a decrease in conservatism and fewer restrictions on the geometry, materials, and loading conditions, but with an increase in effort. Level 1 and 2 assessments tend to have modest data requirements and usually have calculation requirements that are amenable to hand or spreadsheet type calculations. Level 3 assessments, on the other hand, tend to require a numerical, i.e., finite element analysis (FEA), approach, and are usually based on the design by analysis procedures contained in Part 5 of Section VIII, Division 2 of the ASME Boiler and Pressure Vessel code.

In addition to providing procedures to perform the FFS assessments, API 579-1/ASME FFS-1 also contains extensive annexes containing modelling recommendations, material properties, and descriptions of the technical basis and validation upon which the assessment procedures are based; references to the primary research publications are given also in these annexes.

While API 579-1/ASME FFS-1 is quite general in its application, care and experience must be applied when performing an assessment using its techniques. This is where Pi Engineering Inc. can help you. We have extensive experience in applying API 579-1/ASME FFS-1 to challenging problems, and specialize in non-linear, Level 3 assessments. We can help provide peace of mind in confirming that your equipment is safe for continued service, help you rerate it, or tell you how bad you broke it and help you devise a repair strategy to get the equipment back on line as quickly and economically as possible.